When the garbage is thrown from the hands, where will it end up?

Our country's general waste production has officially exceeded 10 million tons. Statistics from the Environmental Protection Agency show that the total amount of general waste in Taiwan reached 9.9 million tons in 2020, and surpassed it again in 2021, reaching 10,062,344 tons. On average, each person produces about 20.6 kg of food waste and 428.5 kg of garbage per year.

Taiwan's waste treatment is dominated by incineration. However, among the 24 incineration plants in Taiwan, more than half of them are more than 20 years old. In the next three years, 14 incineration plants will enter the preparation period. Where should the unburned garbage go?

The era of new energy has come, rich hydrogen will be an important medium to build the future energy system and realize energy transformation, and achieve the government's goal of promoting green energy.

In the past, the comprehensive utilization rate of solid waste (people's livelihood & industry) was low, and the treatment rate was quite low. Most of them were simply piled up, and the old accumulation could easily cause environmental hazards.

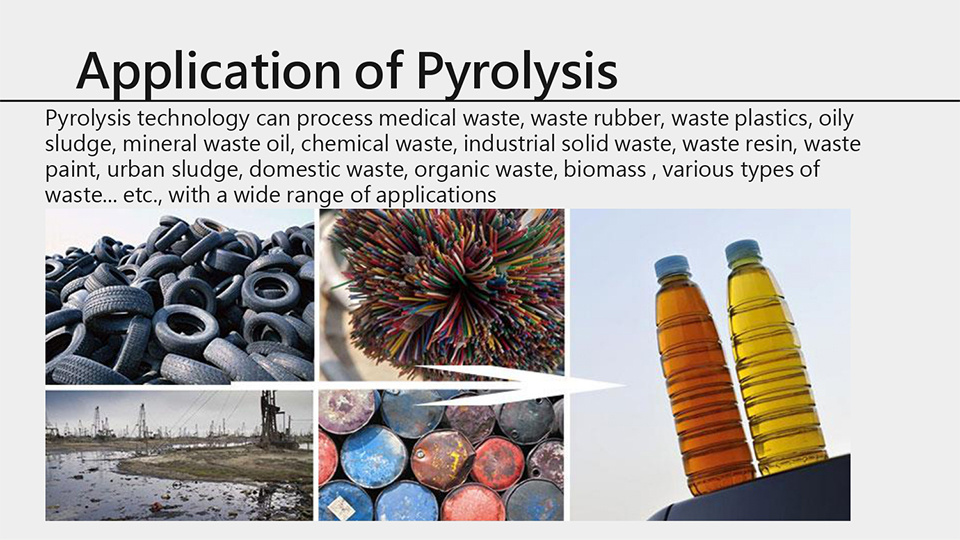

Application:

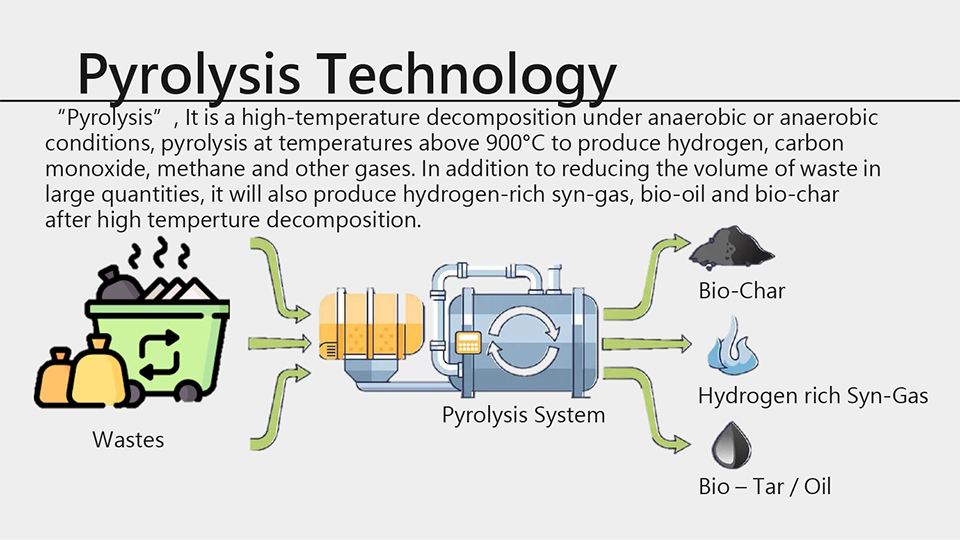

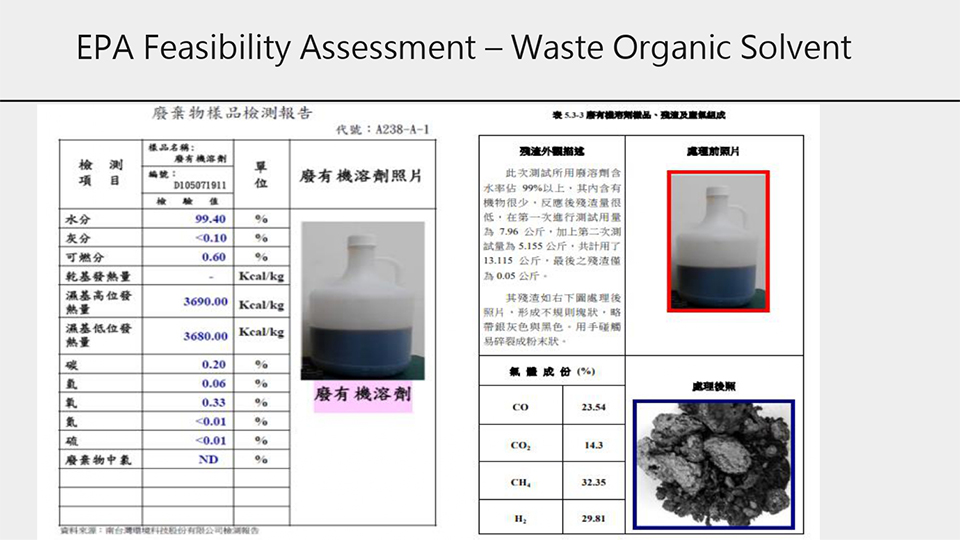

The technology of pyrolysis could be widely applied in waste rubber, waste plastic, sludge, mineral oil, chemical oil, industry waste oil, resin, oil paint, sludge from city, domestic wastes, organic wastes, biomass, and etc.

Pyrolysis is called "Pyrolysis", which is to supply insufficient amount of combustion-supporting air in the combustion chamber, so that the pyrolysis is carried out at a certain temperature (850°C~900°C). After decomposition, hydrogen-rich synthesis gas and pyrolysis carbon black will be produced. After the synthetic gas is cooled and purified, it can pass through the hydrogenation power generation device to generate electricity, and the carbon black can also be reused.

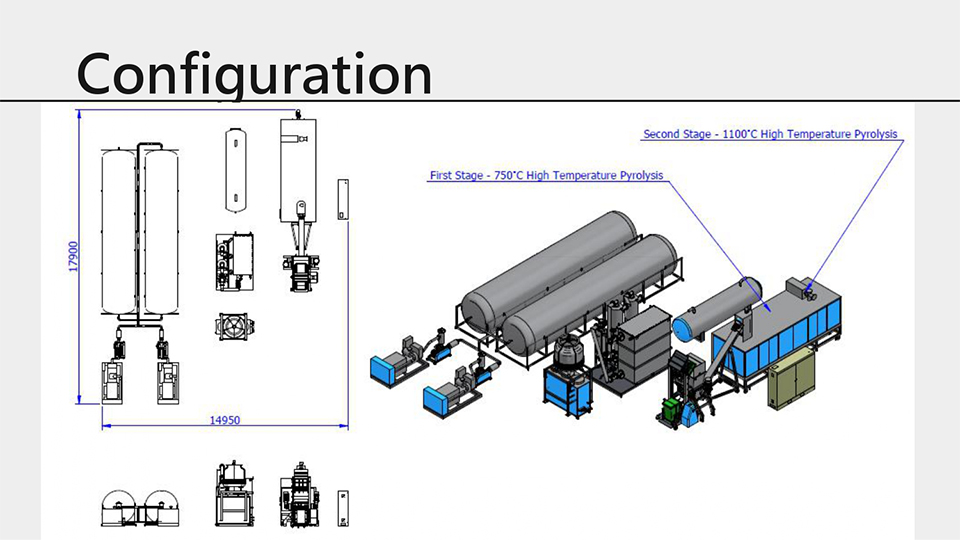

The pyrolysis waste treatment system is divided into the following:

(1)Quantitative automatic feeding system

(2)Combustion chamber

(3)Secondary combustion chamber

(4)Ash system

(5)Waste heat recovery system

(6)Exhaust gas treatment system

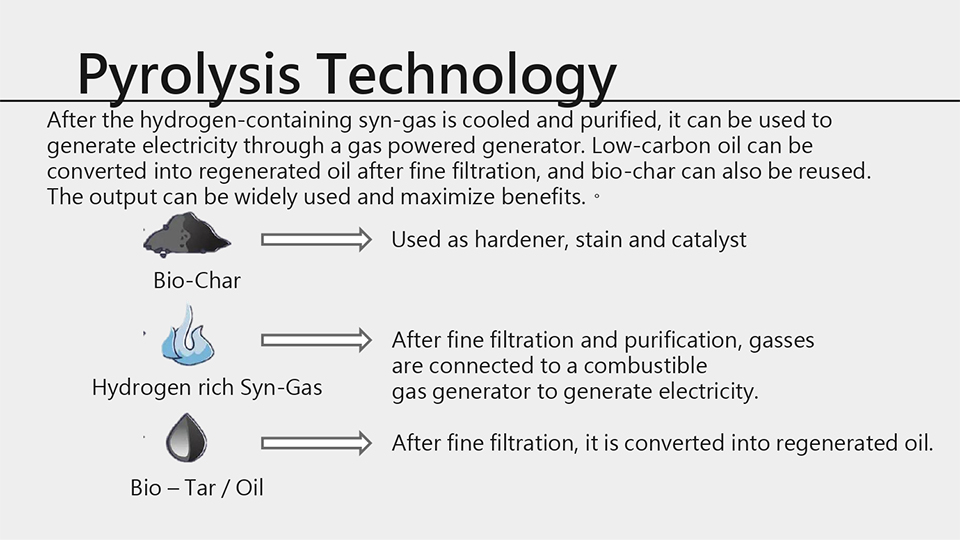

The products in the pyrolysis process allow us to obtain three excellent products, which are the best green energy:

1. Decompose into short-chain organic gases and trace amounts of hydrogen due to high temperature and lack of oxygen during the pyrolysis process, and purify them by fine filtration Generate combustible gas and connect combustible gas generator to generate electricity, which can generate electricity.

2. The residue after pyrolysis and gasification, liquefied tar, can be distilled into light oil.

3. The final relatively pure carbon and the inorganic ash contained in the garbage itself are excellent building material additives or clay.

Combining the above thermal cracking has great economic benefits and good chemical removal, and has great application value.

Pyrolysis of solid waste has the following advantages:

(1)Convert organic matter in solid hazardous waste into stored energy mainly consisting of fuel gas, fuel oil and carbon.

(2)Decompose without oxygen or lack of oxygen, and the exhaust volume is small, which is beneficial to reduce the secondary pollution of the atmospheric environment.

(3) Most of the harmful components such as sulfur and heavy metals in the waste are fixed in carbon black, which does not affect the environment.

(4) The production of nitrous oxide (Nitrous Oxide) is small

(5) Effectively reduce waste volume by more than 95%

After primary crushing and fine crushing, granulation, it enters the thermal cracking equipment above 900 degrees, and after decomposition, hydrogen-containing synthesis gas and carbon black are produced. After cooling and purification, the synthesis gas can be generated through the hydrogenation power generation device, and the carbon black can also be reused.

Domestic Waste Recycling System Patent

Sustainable Development Carbon Management Certificate